Real Stories, Real Risks, and Why Monitoring Matters More Than Ever

Every kitchen has a personality.

Some have the chef who sings, some have the prep cook who never stops organising…

And almost all of them have a fridge with an attitude.

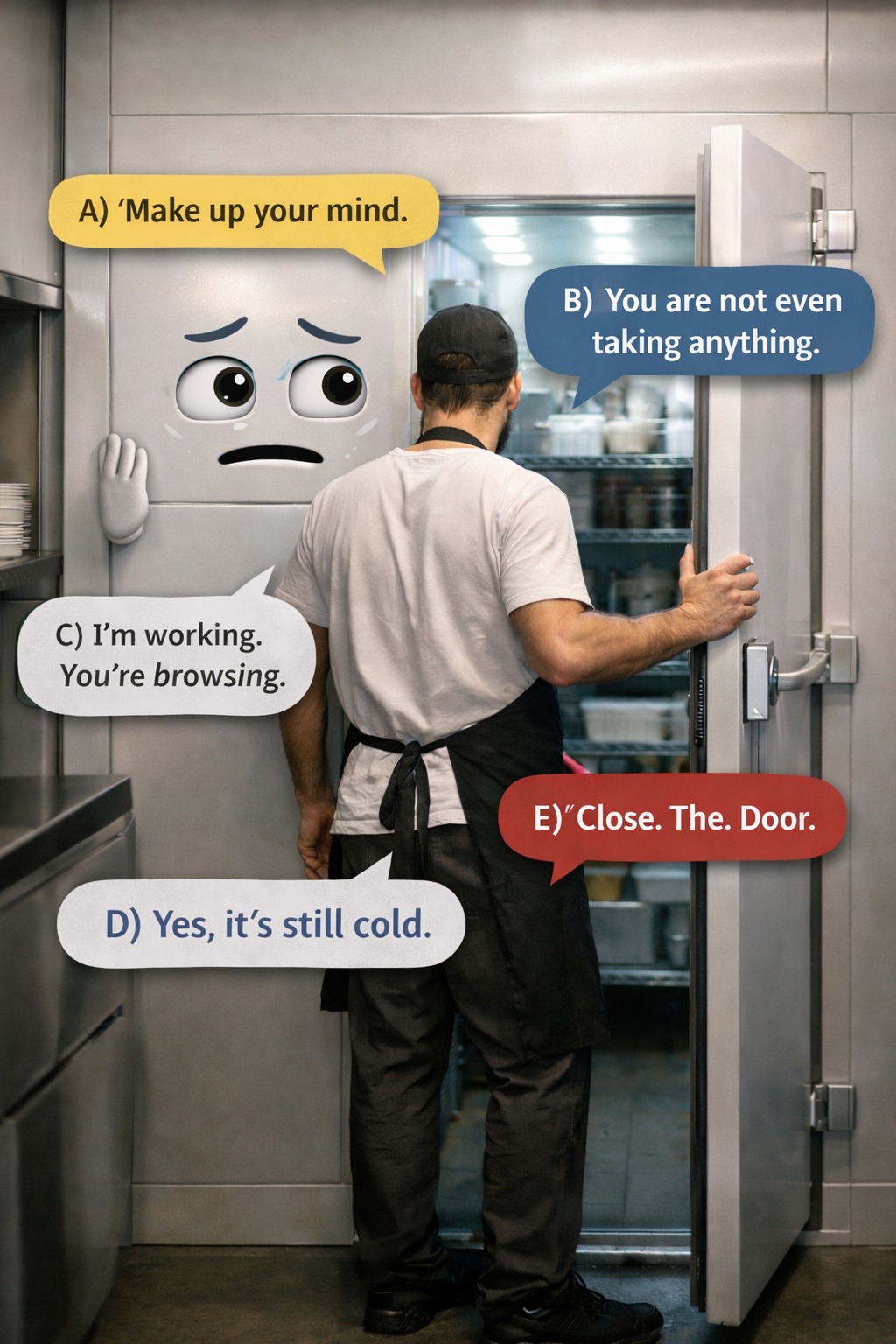

Recently on LinkedIn, we had a bit of fun imagining what commercial fridges would say if they could talk:

“Make up your mind.”

“You’re not even taking anything.”

“I’m working. You’re browsing.”

“Close. The. Door.”

It made people smile — but it also highlighted a more serious truth:

Behind every joke is a genuine challenge we see every day across hospitality, healthcare, education, and more.

Kitchens are busier.

Teams are stretched.

Checks get missed.

Equipment fails without warning.

And no amount of “If fridges could talk…” humour can cover up the reality that manual food safety processes and temperature checks simply don’t catch everything.

The Hidden Issues You Only Discover When You Start Monitoring

We install thousands of sensors across the UK and globally, and one thing happens more often than people expect:

On day one, the system alerts to a fridge or freezer fault no one knew about.

In fact, in many cases the initial reaction is:

“Is the sensor wrong?”

Then someone checks manually…

And realises the sensor was right — the unit was running too warm, too cold, or cycling incorrectly.

This happens because:

Manual checks only capture a single moment in time

Equipment issues usually happen overnight or between shifts

Busy teams don’t always spot early signs of failure

Small fluctuations become big problems very quickly

Continuous, automated monitoring sees what humans simply cannot.

It’s Not Just Hospitality — Other Industries See the Same Challenges

Beyond food service and manufacturing, we’ve expanded across many sectors that face similar pressures:

Healthcare

Hospitals, GP surgeries, pharmacies, and labs rely on stable temperatures for vaccines, medications, samples, and research materials.

A single unnoticed fluctuation can mean thousands of pounds of loss — or put patients at risk.

Education

Schools, colleges, and universities must meet food safety standards across multiple sites and varied equipment, often with limited staffing.

Facilities & Corporate Sites

Server rooms, IT hubs, and temperature-controlled environments need reliable monitoring to prevent downtime or damage.

Cruise Ships & Large Venues

Complex layouts, multiple decks/floors, reinforced walls, and high-volume operations make manual monitoring almost impossible.

Across all these sectors, one theme stands out:

The moment automated monitoring goes in, previously unseen issues appear — and teams finally get the visibility they need.

Why We Add Humour to a Serious Topic

Food safety, compliance, and operational risk aren’t the most exciting subjects on the internet.

But humour opens the door to real conversations.

Posts like “If fridges could talk…” resonate because:

Every chef or manager has lived the experience

Every team has a shared fridge door frustration

Everyone understands that equipment has a “personality”

It makes a serious topic more human

And behind the humour is something important:

A reminder that even the hardest-working fridge needs help keeping its cool.

Moving From Manual to Digital: Why Teams Start Earlier Now

We’ve also noticed another shift:

More businesses are implementing digital food safety and monitoring before they open — especially new restaurants, cafés, central kitchens, and catering sites.

Why?

Staff start with good habits from day one

Training is easier before service pressure begins

There’s no messy transition from paper to digital

The install is smoother when kitchens aren’t fully operational

Issues are spotted before the first plate leaves the kitchen

It sets the tone for compliance from the very first day of trading.

Final Thought: If Fridges Could Talk…

They’d probably say:

“Please install a monitoring system so I don’t get blamed when something goes wrong.”

And honestly?

They’d be right.

Automated monitoring isn’t just a tech upgrade — it’s peace of mind, time saved, waste reduced, and far fewer food safety headaches.

If you’d like to learn how real-time monitoring could help your operation (or your fridge), we’d be happy to chat.